Capabilities Machining & Assemblies

Machining

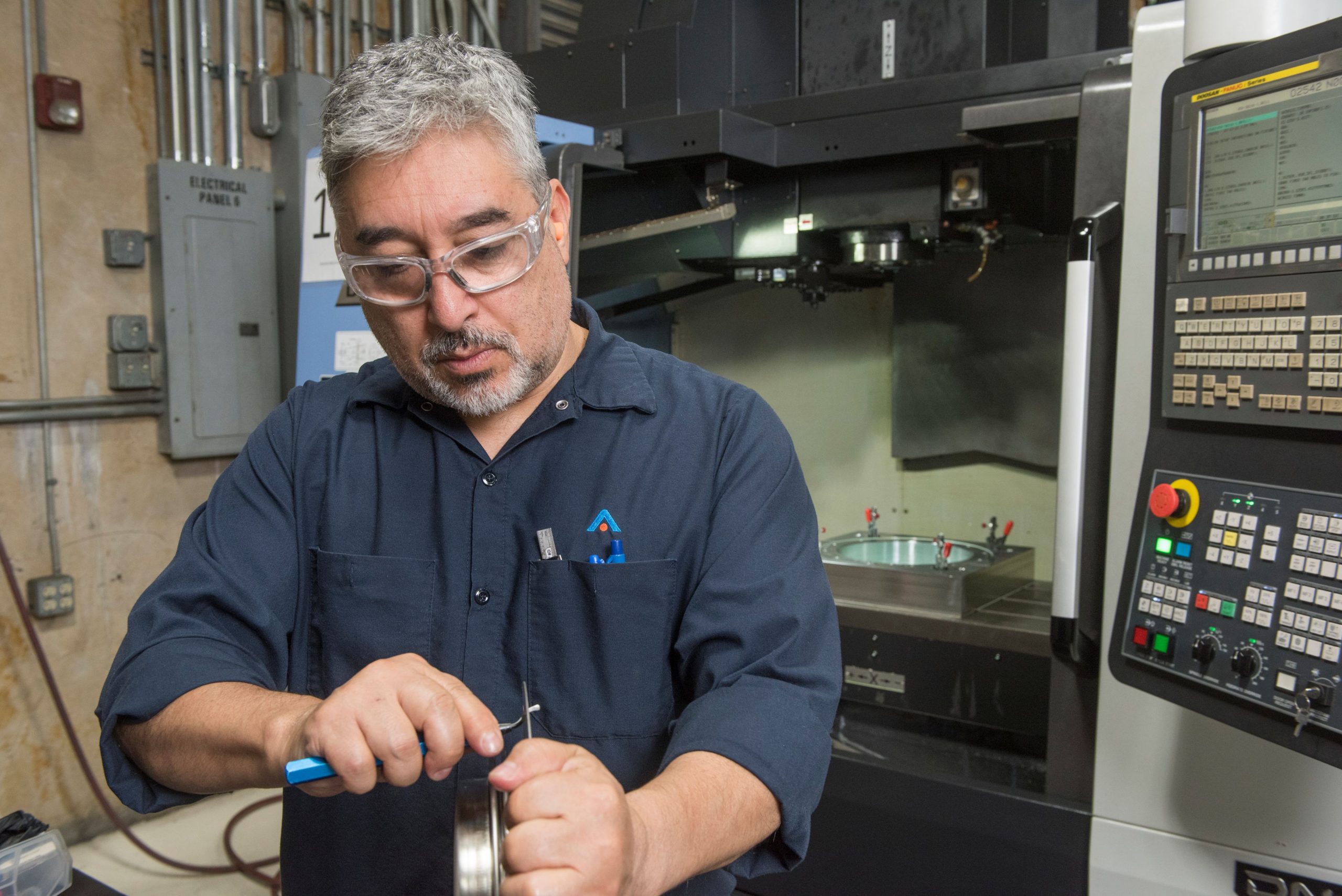

While PMT was initially founded as a parts surplus business, the goal was to ultimately shift focus to manufacturing; this happened just six years after the company was founded. Since 2000, the core of our business operations has revolved around machining and producing complex parts with tight tolerances. From the conception of the lathe to the more recent development of CNC machining, technology has come a long way. We pride ourselves in maintaining a standard of upholding the latest and greatest in machining capabilities, without sacrificing the importance of traditional machining skills. The coalescence of our experienced machinists and technology, such as simultaneous five-axis machining, results in an unmatched product that is sure to meet any standard it is put up against. PMT was, at one point, a HAAS shop, however, we have recently begun to compound our ceaseless need for perfection through a transition to machinery, DMG Mori and Doosan, that can hold much tighter tolerances and offer far superior finishes. The synthesis of these byproducts guarantees that every part that leaves PMT’s facility is flawless.

We work with virtually any and every material applicable to the aerospace industry. From all common aluminum alloys and steels, to tougher material such as Inconel and titanium, PMT has you covered. Our decades of experience working with practically any material imaginable has allowed us to perfect our methods and ensure that your part arrives just as it should be, if not better.

Assemblies

We aren’t just a parts manufacturer; we are experienced in the assemblage of components to create a desired final product; the application of bushings, bearings, fasteners, and adhesives to parts that we machine in-house allows us to serve as a one-stop-shop capable of fulfilling any of your needs. Our well-structured organizational system allows us to complete detailed assemblies, component by component, in a timely manner and ultimately construct a final product that is sure to exceed expectations. Many of the assemblies that we have manufactured consist of hundreds of individual pieces, each of which complex in its own way; we plan these jobs in a manner that provides our customer with a finished product in record time. Our team’s wide breadth of expertise allows us to complete many complex processes in-house, diminishing the delays that would be expected at other shops around the country.

We are proud to support the following aircraft

| B-1 | F4 |

| B-2 | F-5/T-38 |

| B-52 | F-15 |

| C-5 | F-16 |

| C-17 | F-18 |

| C-130 | F-22 |

| E-2 | F-35 |

| E-3 | KC-46 |

| E-6 | KC-135 |